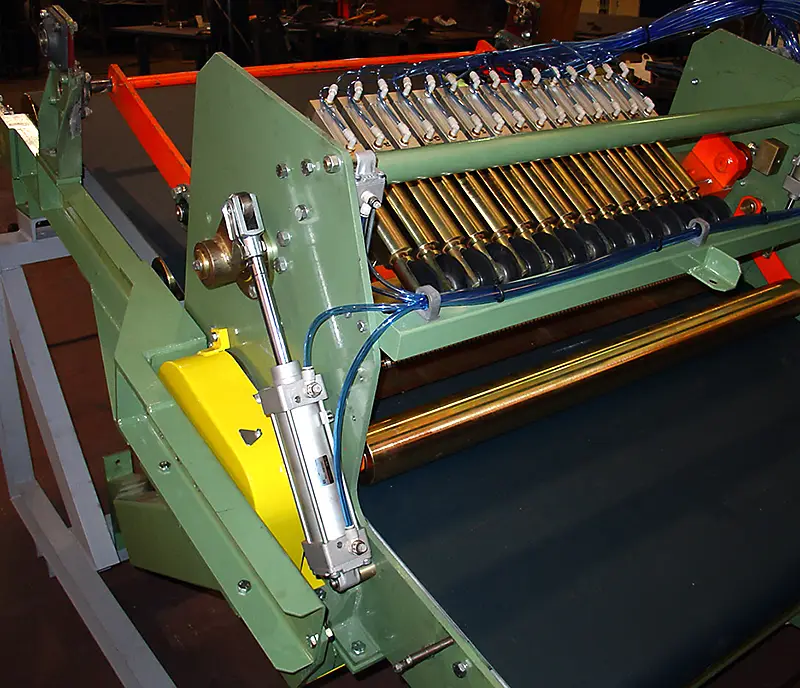

Longitudinal cutting system (cold and hot)

Longitudinal cutting systems can be placed before batch-off, to perform a hot cut, or after batch-off to perform a cold cut.

Hot cutting can be carried out either directly on the cylinder or on the inlet group, just before the anti-tack agent application. Cold cutting takes place just after the batch-off.

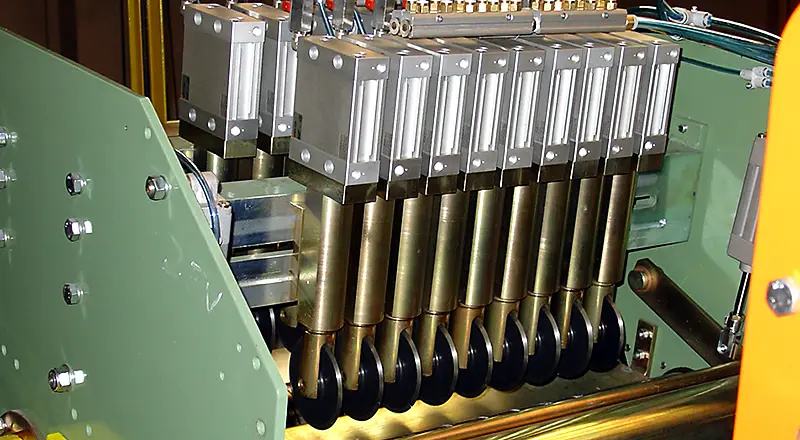

RubberMat® longitudinal cutting systems consist of three distinct parts:

The drive of the cutting units can be automated to a greater or lesser degree depending on the needs of the application. The maximum degree of automation allows remote control of the drive of each blade separately, as well as its position.

| TECHNOLOGY | TYPE OF SUPPORT FOR CUTTING UNITS | MINIMUM CUTTING WIDTH (MM) |

|---|---|---|

| Manual | 40mm | |

| Automatic | 60mm | |

| Hot cutting | Manual / automatic | 28mm |

Other rubber production equipment

In addition to longitudinal cutting system, we manufacture specialized machinery to properly equip companies dedicated to rubber production and processing.

Transport

Cutting systems

Peripherals ans accessories