Air cooling lines (BATCH-OFF)

These equipments are used for cooling rubber bands or strips. Depending on the characteristics of the product, air or water immersion cooling is used.

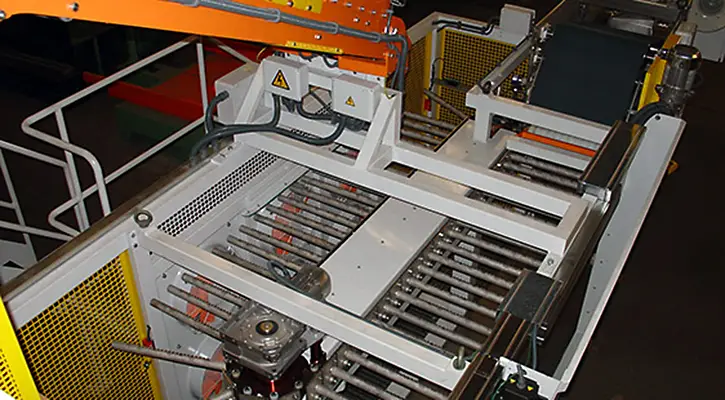

The air cooling lines consist of two units: the anti-tack agent application unit (inlet group) and the cooling tunnel.

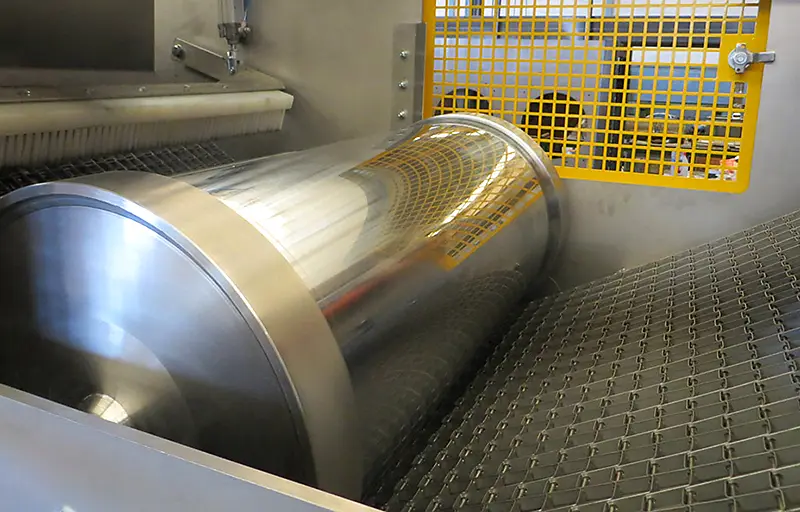

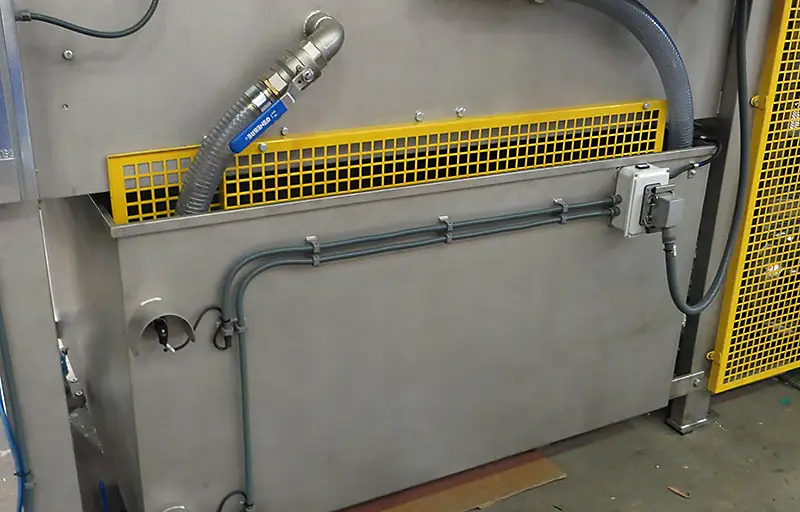

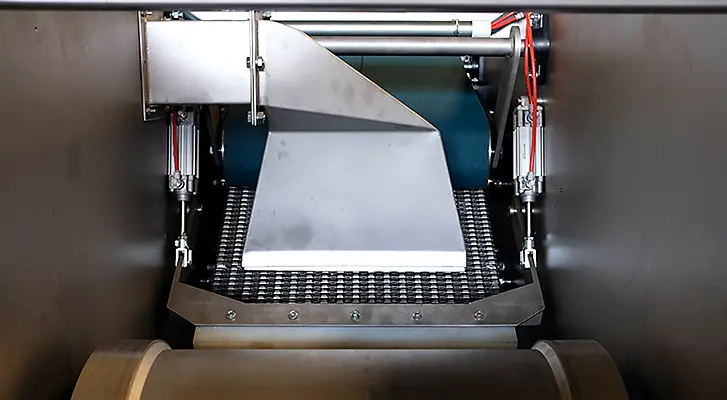

The inlet group is the unit that receives the rubber band or strips from an extruder or an open mill. These bands or strips of rubber are dragged towards the interior of the immersion tank, place in which, they are submerged in water with anti-tack agent in a first phase.

Then, they are drained and dried by a mixed mechanical-air system to be delivered later to the cooling tunnel.

On certain occasions, the water in the inlet group is cooled to carry out a first cooling phase.

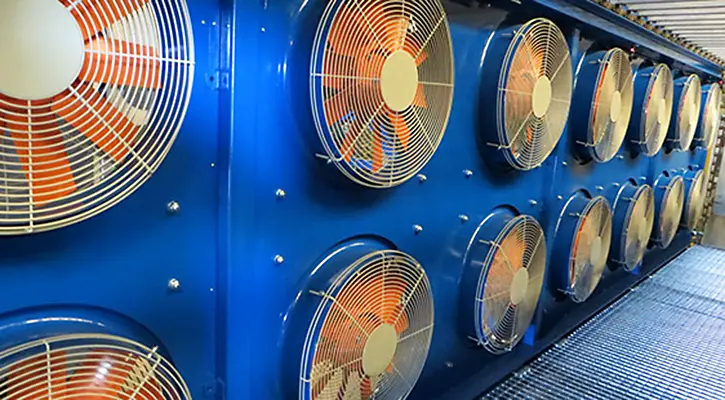

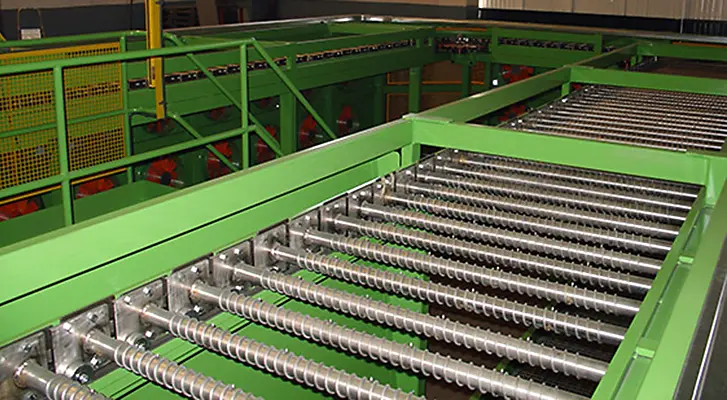

The cooling tunnel is a tunnel itself, with the hot rubber strips entering at one end and exiting cold at the opposite end. Cooling tunnels are made up of several sets of fans that project fresh air through the strips to reduce their temperature.

These strips or rubber bands, hung on hangers, advance along the tunnel, step by step, at the programmed speed according to the rubber production for which it has been designed.

Other rubber production equipment

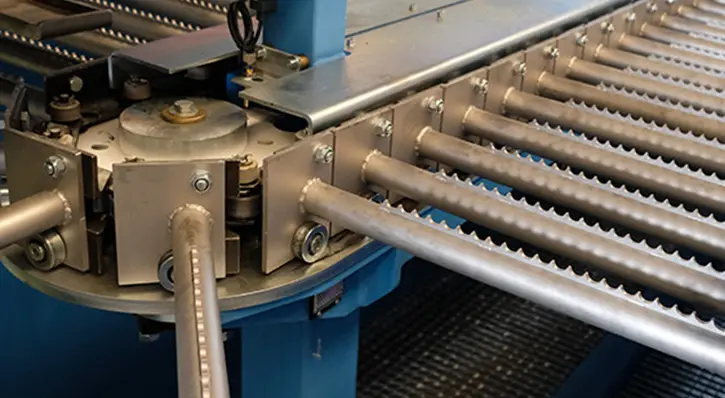

In addition to rubber cooling tunnels, we manufacture specialized machinery to properly equip companies dedicated to rubber production and processing.

Transport

Cutting systems

Peripherals and accessories